1. Introduce

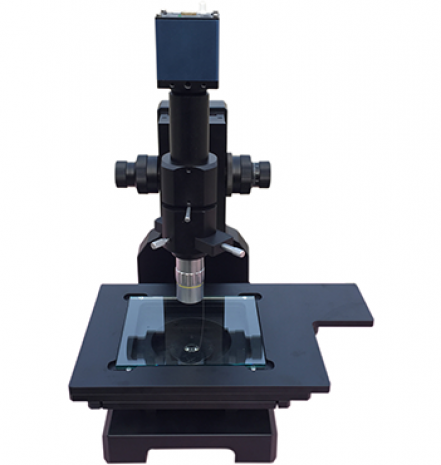

XSK400 microscope is an infinite range optical system, long working distance flat field compound chromatic aberration objective lens, stable and reliable frame, accurate focusing mechanism.Lighting with LED shaft light source and LED transmission light source.The polarization system can adjust the rotation of 100 degrees for orthogonal observation.The best differential interference effect can be obtained by adjusting the DIC prism inserting plate mechanism.Large visual field single eye observation, reduce a lot of intermediate links, make imaging more clear and better.A high-definition analog camera can capture high quality images quickly.

The XSK400 microscope is reliable, easy to operate and has clear imaging.Widely used in semiconductor, electronic industry.The examination and scientific research of crystal and integrated circuit.An analog camera can be configured to take, store, measure and analyze the observed samples.

USES:

1. Open field observation: the use of brightness adjustable coaxial lighting, crystal, IC inspection, precision manufacturing assembly, parts testing and quality control.

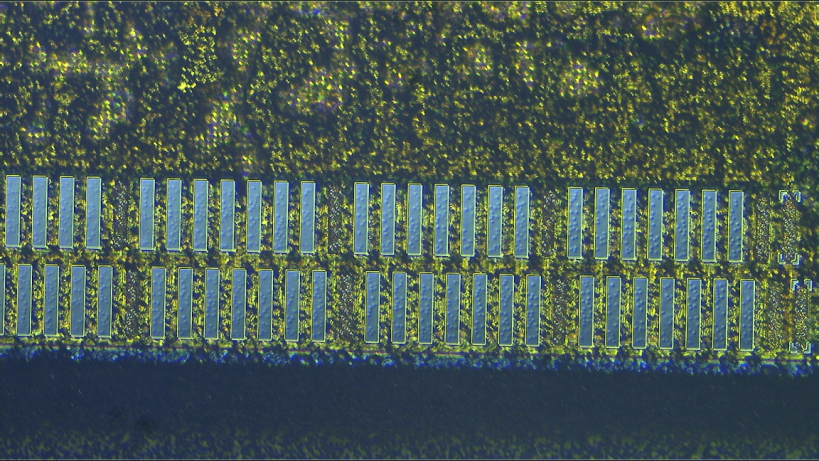

2. Transmission observation: adopt brightness adjustable transmission lighting to observe transparent samples. Especially, it has better detection effect on the LCD screen, and can clearly see the tricolor module of the luminescent screen. Therefore, it can detect the quality of the display screen and judge its quality.

3. Polarizing observation: the polarizing mechanism is installed in the system, and the polarizing mirror is fixed in the lighting system.In the imaging system, the rotation of 100 degrees can be adjusted to facilitate orthogonal observation.Orthogonal polarized light observation of metallographic samples can also be applied to mineral and chemical fields.

4.DIC observation -- differential interference observation: insert the DIC prism device (wollaston prism) again in the system of bright field and polarized light.(DIC) as one of the most promising analytical test methods, has low requirements for the preparation of metallographic specimen, observed the sample of the relative level of relationship between each component is outstanding, is obvious embossment, of particles, cracks, holes and bump can make the right judgment, can easily determine many invisible to the field or is difficult to distinguish some structure details or defects, can be color metallographic photography, etc.However, in the current metallographic inspection work, (DIC) method is still used very little.Especially, it is better to detect the conductive particles on the conductive plate of the LCD.By using DIC technology, the slight difference on the surface of the object can be displayed clearly, with prominent contour and three-dimensional relief imaging, which greatly improves the contrast of the image.

2. Image

Specification | XSK400 | XSK400A | |

Optical System | Infinity optical system f=200mm | ● | ● |

Polarization | 0°-105° | ● | ● |

Nosepiece | Simply | ● | ● |

Quintuple | ○ | ○ | |

DIC | 0-10mm insert board | ● | |

Objective | Plan 95mm APO 1X/0.015 WD=14mm | ○ | |

Plan 95mm APO 2X/0.05 WD=20mm | ○ | ||

Plan 95mm APO 5X/0.012 WD=23mm | ● | ○ | |

Plan 95mm APO 10X/0.30 WD=34mm | ○ | ○ | |

Plan 95mm APO 20X/0.30 WD=33mm | ○ | ○ | |

Plan 95mm APO 50X/0.50 WD=20.7mm | ○ | ||

Plan 95mm APO 100X/0.80 WD=4.0mm | ○ | ||

Plan 95mm APO 150X/0.60 WD=4.4mm | ○ | ||

Plan 95mm APO 200X/0.65 WD=2.2mm | ○ | ||

Plan 95mm APO 250X/0.70 WD=2.0mm | ○ | ||

Plan 95mm APO 500X/0.75 WD=1.96mm | ● | ||

Stage | Double layers stage 220×260mm, | ● | ● |

Glass stage 170x150mm | ● | ● | |

Moving range: 75×75mm | ● | ● | |

Motorized Stage | ○ | ○ | |

Focus System | Coaxial coarse and fine with rack and pinion, coarse range 60mm, fine scale value 0.002mm | ● | ● |

Illumination | Reflected LED | ● | ● |

Optional Accessories | ○ | ○ | |

Note: "●"In Table Is Standard outfits, "○" Is Optional Accessories.

1

1